One of the final challenges is the layout of the Hunter Douglas linear metal panel ceiling system. The idea is to have a random patterned ceiling. But since the lighting needs to be distributed equally, it must also have some repeating elements. With all projects, very little of the time, it is a linear progression (no pun intended : ). The lighting was specified before the ceiling concept was finalized. So once it was confirmed that we were to have different panel widths and depths, we had to make it work.

One of the final challenges is the layout of the Hunter Douglas linear metal panel ceiling system. The idea is to have a random patterned ceiling. But since the lighting needs to be distributed equally, it must also have some repeating elements. With all projects, very little of the time, it is a linear progression (no pun intended : ). The lighting was specified before the ceiling concept was finalized. So once it was confirmed that we were to have different panel widths and depths, we had to make it work.

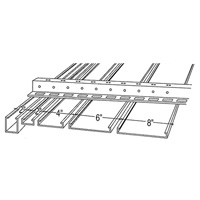

The overriding pattern is the lighting layout. And since there were two different types of lighting, linear and recessed, their spacing is different. This meant that in those areas a repeating panel size and depth had to occur. Once those two patterns are laid out, the rest of the panels are laid out randomly. This makes a custom ceiling design, but it is the fastest way to lay out the ceiling. Once the install begins, the panels are flexible with the exception of the panel with lights. So if we come across field conditions that need to have a panel cut, we can instead switch to a smaller panel to forgo cutting any panels. This will give the system a seamless well designed look (see image 2).

Click here to see the final ceiling installed. Tell us what you think!